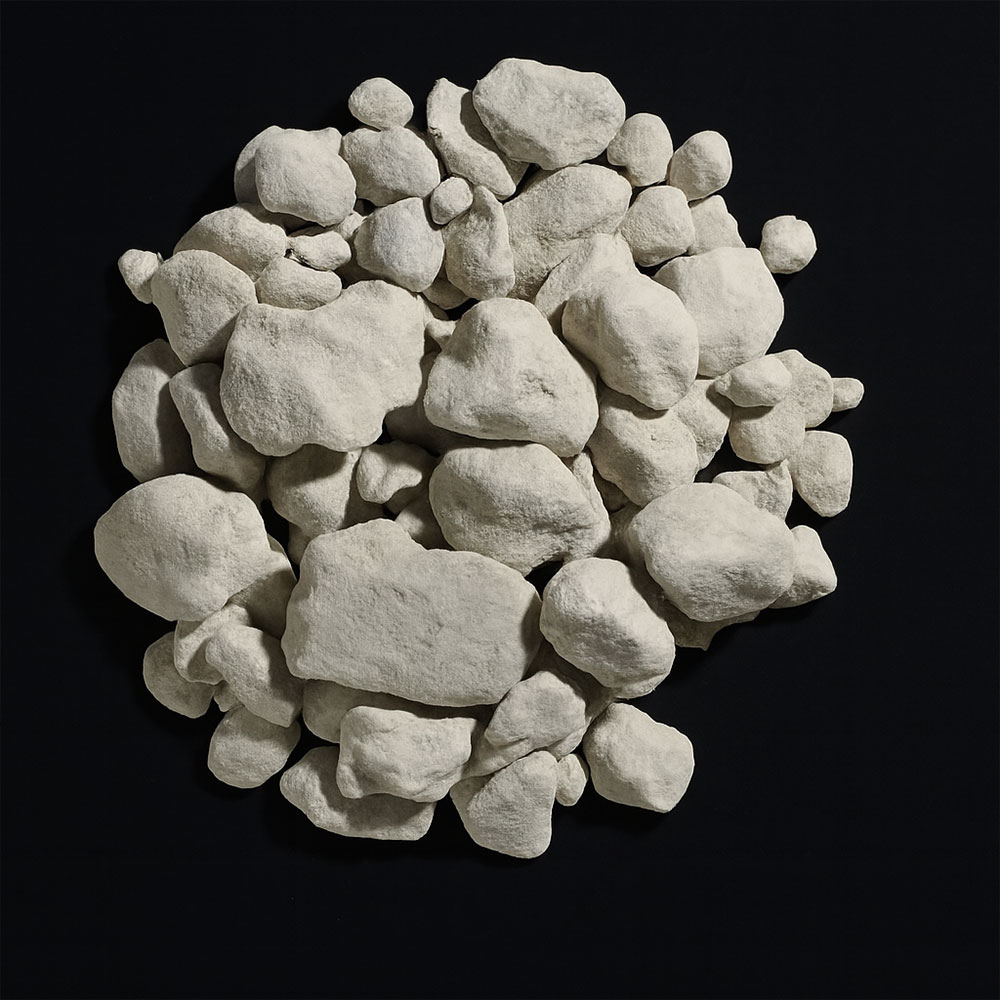

Ball Clay

Ball Clay is a highly plastic, fine-grained natural clay used widely in ceramics for shaping and strength. It improves workability, controls shrinkage, and enhances body consistency. Ideal for sanitaryware, tiles, and tableware, its high bonding strength and refractory nature make it essential in forming complex shapes with minimal cracking. We offer Ball Clay in multiple grades to suit various industrial applications with superior blending and plasticity performance.

Properties :

- Excellent Plastic Strength

- Superior Workability Properties

- Enhances Body Uniformity

- Low Shrinkage Rate

- Multiple Grade Availability

Products InquirySpecification

| Property | LS1 | LS2 | BA-1 | KA-1 | RD2 | TI | SN1 | WHITE CLAY |

|---|---|---|---|---|---|---|---|---|

| Chemical Properties | ||||||||

| Silica (SiO₂) | 51.09% | 64.38% | 44.81% | 50.71% | 55.38% | 52.14% | 47.02% | 50.02% |

| Alumina (Al₂O₃) | 23.06% | 23.46% | 35.48% | 31.34% | 28.56% | 30.12% | 35.72% | 30.44% |

| Iron (Fe₂O₃) | 1.1% | 0.83% | 1.08% | 1.05% | 1.2% | 1.15% | 1% | 1.2% |

| Titanium (TiO₂) | 1.12% | 1.22% | 1.18% | 1.12% | 1.80% | 1.21% | 1.26% | 1.21% |

| Calcium (CaO) | 0.32% | 0.31% | 1.19% | 1.18% | 0.32% | 0.98% | 0.31% | 0.38% |

| Magnesium (MgO) | 0.27% | 0.42% | 0.51% | 0.40% | 0.46% | 0.37% | 0.29% | 0.41% |

| Potassium (K₂O) | 1.17% | 0.91% | 0.5% | 0.51% | 1.56% | 1.37% | 0.69% | 0.41% |

| Sodium (Na₂O) | 0.24% | 0.30% | 0.89% | 0.61% | 0.79% | 0.74% | 0.24% | 0.38% |

| Loss on Ignition (L.O.I) | 11.23% | 7.89% | 14.05% | 11.57% | 11.01% | 11.38% | 13.14% | 12.0% |

| Physical Properties | ||||||||

| L Value | 90.87% | 90.24% | 85.16% | 84.16% | 82.61% | 84.95% | 91.30% | 87.91% |

| A Value | 1.40% | 1.12% | 2.12% | 1.61% | 2.37% | 1.58% | 0.35% | 0.99% |

| B Value | 8.26% | 8.04% | 7.14% | 17.45% | 15.37% | 14.44% | 10.32% | 6.44% |

| Whiteness | 78.25% | 76.82% | 66.14% | 65.19% | 61.41% | 63.15% | 79.54% | 72.14% |

| Temperature °C | 1195/1207 | 1195/1207 | 1195/1207 | 1195/1207 | 1195/1207 | 1195/1207 | 1195/1205 | 1195/1207 |

| Cycle Min | 45% | 45% | 45% | 45% | 45% | 45% | 48% | 50% |

| Residue(#240) | 0.19% | 1.19% | 1.01% | 0.78% | 0.15% | 0.29% | 1.06% | 0.22% |

| TDS | 570 | 260 | 210 | 470 | 610 | 820 | 800 | 570 |

| Shrinkage | 7.13% | 4.92% | 11.66% | 8.84% | 9.91% | 8.17% | 11.71% | 11.1% |

| Fired M.O.R (kg/cm²) | 287.2 | 237.5 | 236.3 | 325.8 | 229.7 | 346.4 | 229.3 | 304.5 |

| Dry M.O.R (kg/cm²) | 25.4 | 22.6 | 23.4 | 25.9 | 24.3 | 24.6 | 22.2 | 23.5 |

| Water Plasticity | 40.4% | 30.4% | 34.2% | 32.6% | 34.6% | 35.2% | 35% | 35% |

| Water Absorption | 11.36% | 14.66% | 6.82% | 4.84% | 6.43% | 6.43% | 10.23% | 4.66% |

| Loss On Ignition | – | – | 13.75% | 11.70% | 11.09% | – | 13.20% | 11.17% |